Ursapharm Saarbrücken, Germany

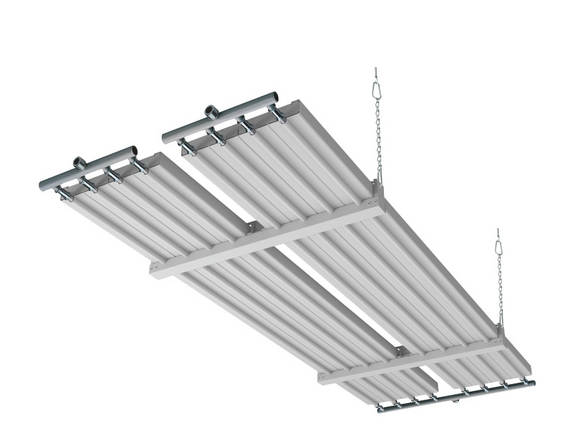

Heating and Cooling Ceiling Systems for High-Bay Warehouses

Ursapharm Arzneimittel GmbH is one of the world’s leading manufacturers of ophthalmic products. Today, the company employs more than 650 people. Expanding the logistics area became necessary in 2016 for the steadily growing business operations of this pharmaceutical company, resulting in the construction of a new high bay warehouse and an adjacent block warehouse with a total area of 5,900 m². Both halls were completed in accordance with the EnEV standard in the autumn of 2018.